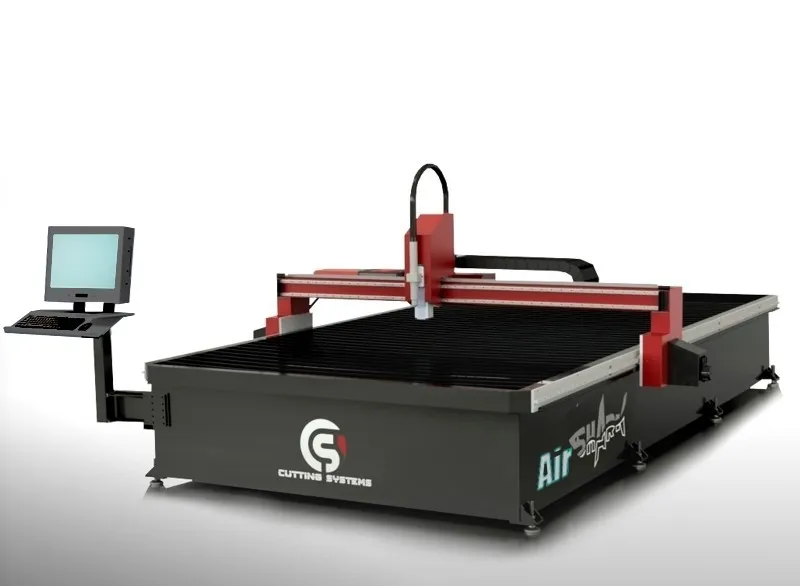

Shark CNC Plasma Cutting Machine

Quick Specs

- Cutting Process = Plasma & OxyFuel

- Sizes = 4×8, 5×10, and 6×12’

- Cutting Thickness = 2” Plasma, 3” Oxyfuel

- Hypertherm Plasma = 200 – 400 amps

- Oxyfuel = 1 Torch (Optional)

- Water/Downdraft Tables and Dust Collectors

Product Description

The Shark CNC Plasma Cutting Machine is a unitized system designed for industrial-grade precision and durability. It is perfect for light to medium industrial applications, supporting plate cutting up to 2″ thick for plasma cutting and up to 3” thick for oxyfuel cutting, and rapid traverse speeds of up to 1000 IPM. Available in standard table sizes of 4×8, 5×10, and 6×12, it provides robust functionality at an affordable price point.

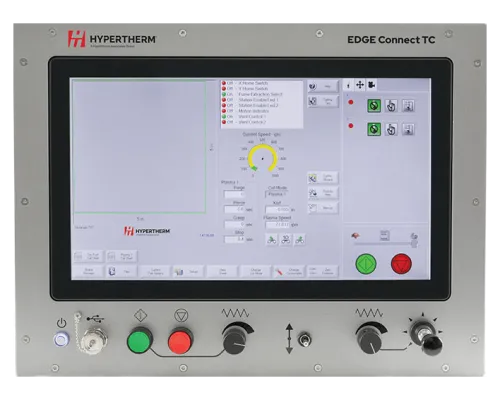

The Shark HD CNC Plasma Cutting Machine delivers industrial-level performance with features tailored to maximize efficiency and precision. Its unitized welded steel construction ensures stability and durability. Its advanced Hypertherm ProNest software optimizes material usage, while the integrated Hypertherm Edge Connect CNC controller simplifies operation. Designed for ease of setup and use, the Shark is a versatile solution for manufacturers and fabricators seeking reliable, cost-effective cutting solutions.

Standard Equipment

Unitized Table Construction

Hypertherm Plasma Power Supplies

Reliable Yaskawa Drive System and Servo Motors

Shark HD CNC Plasma Cutting Machine with Hypertherm CNC Controller

The Shark HD CNC Plasma Cutting Machine is a robust, industrial-grade system for precision and efficiency in light to medium fabrication applications. When paired with the Hypertherm EDGE Connect CNC Controller, the Shark HD becomes a powerhouse of automated cutting, offering unmatched control, ease of use, and reliability.

How the Hypertherm CNC Controller Enhances the Shark HD

- Automated Precision Cutting: The Hypertherm CNC Controller transforms the Shark HD into a fully automated cutting solution, capable of executing complex shapes and repetitive tasks with exceptional accuracy.

- Intuitive Operation with Phoenix Software: The Shark HD’s Hypertherm Phoenix® version 10 CNC software provides a user-friendly interface, making it easy for operators of all skill levels to program and execute cutting tasks. The patented CutPro® Wizard allows even novice operators to start cutting production parts in less than five minutes.

- Real-Time Monitoring and Diagnostics: The Soft Operator’s Console (Soft OpCon) provides real-time monitoring of key cutting parameters, such as torch height, amperage, and gas flow.

- Easy Integration: The Shark HD’s Hypertherm EDGE Connect CNC Controller integrates seamlessly with Hypertherm plasma power supplies, including the XPR 170, XPR 300, and HPR 400.

- Improved Reliability: Designed for industrial use, the Shark HD’s CNC controller features a fan-less quad-core processor, solid-state hard drive, and projected capacitive touchscreen.

- Customizable Performance: The EDGE Connect CNC Controller offers flexible configurations to meet specific cutting needs. Whether you’re working with plasma, oxyfuel, or waterjet, the controller can be customized to your application.

Lower Maintenance = High Performance

Automatic Lubrication System

The system minimizes wear on moving parts, reducing downtime and ensuring consistent performance.

Automatic Rail Scrubbers

Keep the linear guide rails clean for smoother and more accurate movement, even in demanding environments.