Raptor CNC Plasma Cutting Machine

Quick Specs

- Cutting Process = Plasma

- Cutting Widths = 6’ – 30’

- Cutting Lengths = 10’ – 250’

- Cutting Thickness = 6.25” Plasma

- Hypertherm Plasma = 200 – 800 amps

- Water/Downdraft Tables and Dust Collectors

Product Description

Cutting Systems Raptor is engineered for precision and power, with exceptional CNC plasma cutting capabilities in an industrial-strength design. It supports multiple plasma systems and custom configurations to provide high-definition, accurate cuts across a variety of material types and thicknesses.

The Raptor features a solid steel bridge machined for rigidity, automated features for reduced maintenance, streamlining complex cutting tasks, reducing production time, and improving efficiency.

Standard Equipment

Industrial Strength Construction

Hypertherm Plasma Power Supplies with Sensor THC Automatic Torch Height Controls

Equipped with Hypertherm plasma power supplies and Sensor THC, the Raptor maintains optimal cutting heights for plasma torches, ensuring precise, high-quality cuts.

Reliable and Accurate Yaskawa Drive System, Powerful AC Servo Motors, and Precision Gearboxes

The Raptor utilizes the Yaskawa drive system, AC servo motors, and precision gearboxes, offering smooth, accurate movement that enhances both speed and precision. This advanced drive system minimizes maintenance requirements and ensures reliable operation.

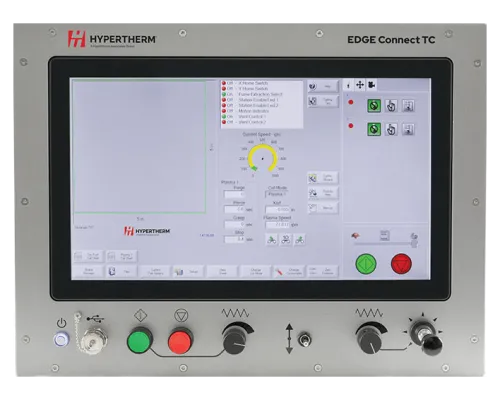

Raptor Cutting System with Hypertherm CNC Controller

The Raptor Cutting System is designed for high-speed, precision cutting in demanding production environments. When paired with the Hypertherm CNC Controller, the Raptor delivers speed, accuracy, and automation for high-volume manufacturing.

How the CNC Controller Enhances the Raptor

- High-Speed Automation: The CNC Controller enables the Raptor to perform rapid, automated cutting, making it ideal for industries like automotive, aerospace, and metal fabrication.

- Precision at Scale: The controller ensures consistent, high-quality cuts across large production runs, even for complex shapes and tight tolerances.

- Optimized Cutting Paths: The Raptor and CNC Controller work together to decrease cycle times and maximize material usage, improving overall efficiency.

- System Monitoring: The controller tracks performance in real-time, providing alerts for potential issues and ensuring uninterrupted operations.

- Streamlined Workflow: The CNC Controller simplifies programming and operation, allowing operators to focus on productivity rather than manual adjustments.

Lower Maintenance = High Performance

Automatic Lubrication System

An automatic lubrication system keeps the Raptor in peak condition with minimal maintenance effort, reducing downtime and extending the lifespan of critical components.

Automatic Rail Scrubbers

Integrated rail scrubbers ensure that the Raptor’s rails remain free of debris, enhancing the accuracy and smoothness of movement while further reducing maintenance needs.

Preventative Maintenance Kits

Engineered to Order

The Raptor Cutting System offers flexible configurations to suit a variety of needs, including custom bridge widths up to 30 feet, I-beam rail systems, multiple plasma options, and preventative maintenance kits. Plasma consumables are also available to keep your system running smoothly and ensure reliable performance for high-demand applications.