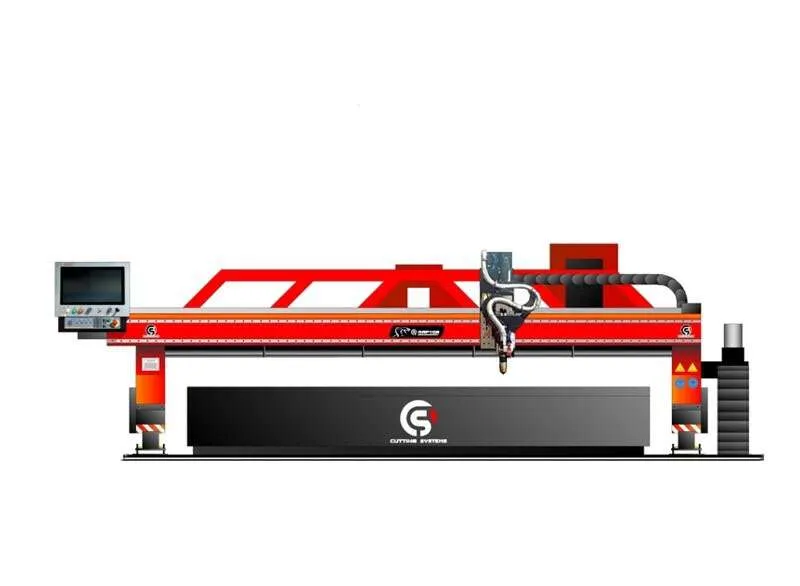

Cobra Bevel CNC Plasma Cutting Machine

Quick Specs

- Cutting Process = Plasma & OxyFuel

- Cutting Widths = 6’ – 30’

- Cutting Lengths = 10’ – 250’

- Cutting Thickness = 6.25” Plasma, 24” Oxyfuel

- Hypertherm Plasma = 200 – 800 amps

- Oxyfuel = 1 – 4 Torches Standard

- Water/Downdraft Tables and Dust Collectors

Product Description

Cutting System’s Cobra is the ultimate automatic CNC plasma bevel-cutting solution, providing unmatched accuracy and efficiency. Engineered for industrial use, it’s designed to eliminate time-consuming manual weld prep processes, making weld-ready parts in a fraction of the time.

Its robust construction and advanced Hypertherm plasma systems allow precise angles and cuts, creating a versatile system ideal for demanding applications in various industries. The Cobra’s customizable configuration includes a high-definition plasma bevel torch and up to four oxyfuel torches, adapting to unique application requirements with ease.

Standard Equipment

Industrial Strength Construction

The Cobra’s fully machined and welded beams and trucks provide exceptional stability and strength, ensuring precise cuts across long spans. A solid steel bridge, precisely machined for rigidity, supports accurate alignment and stability even in high-demand operations.

Hypertherm Plasma Power Supplies and Harris Oxyfuel Torches with Automatic Lifters

Reliable Yaskawa Drive System, Powerful AC Servo Motors, and Precision Gearboxes

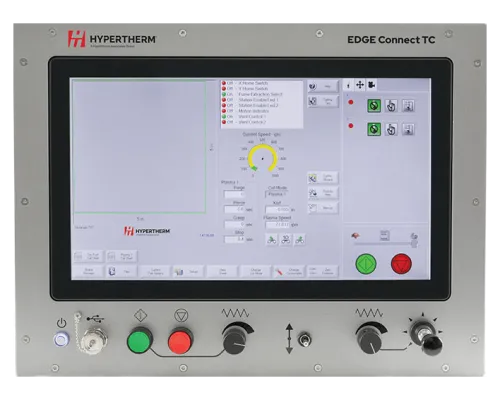

Cobra Cutting System with Hypertherm CNC Controller

The Cobra Cutting System is a versatile plasma cutter for workshops and on-site repairs. When equipped with the Hypertherm CNC Controller, it can handle automated cutting tasks with precision and efficiency.

How the CNC Controller Enhances the Cobra

- Automated Versatility: The CNC Controller enables the Cobra to execute intricate cutting patterns and repetitive tasks, making it an excellent choice for small to medium fabrication shops.

- Portable Automation: While the Cobra is known for its portability, the CNC Controller adds the ability to perform automated cutting, perfect for on-site jobs that require precision.

- Customizable Programs: Save and recall cutting programs for commonly used shapes and materials, reducing setup time and improving workflow.

- Dynamic Adjustments: The controller automatically adjusts cutting parameters to maintain optimal performance, even on differing material thicknesses.

- User-Friendly Operation: The CNC Controller’s straightforward interface makes programming and executing cutting tasks easy, even for less experienced operators.

Lower Maintenance = High Performance

Automatic Lubrication System

An integrated automatic lubrication system reduces downtime and ensures the system remains in optimal condition, significantly lowering maintenance costs and enhancing machine longevity.

Automatic Rail Scrubbers

Automatic rail cleaners keep the Cobra’s rails clear of debris, further reducing maintenance efforts and enhancing the overall smoothness and precision of movement.

Preventative Maintenance Kits

Preventative maintenance kits are available to keep the Cobra operating at peak efficiency, extending the life of your system and preventing costly downtime.

Custom System Configuration Options

The Cobra offers flexible configuration options, including custom bridge widths up to 30 feet, additional oxyfuel stations, I-beam rail systems, and preventive maintenance kits. Plasma consumables are also available to keep your system in top condition and ready for high-performance cutting.