Sabercut CNC oxyfuel Cutting Machine

Quick Specs

- Cutting Process = OxyFuel

- Cutting Widths = 6’ – 30’

- Cutting Lengths = 10’ – 250’

- Cutting Thickness = Up to 24” Oxyfuel Cutting

- Oxyfuel = 1 – 12 Torches Standard

- Water/Downdraft Tables and Dust Collectors

Product Description

The SaberCut system is a versatile, high-precision CNC oxyfuel cutting machine. Featuring multiple cutting stations and effective cutting widths ranging from 6 feet to a massive 30 feet, it meets the rigorous demands of heavy industry applications. Built with a solid steel bridge for stability, SaberCut delivers unmatched accuracy and durability in every cut.

Standard Equipment

Industrial Strength Construction

Designed with fully machined and welded beams and trucks, SaberCut’s construction provides a robust frame that withstands heavy usage in industrial settings. The solid steel bridge is engineered for precision and long-term durability.

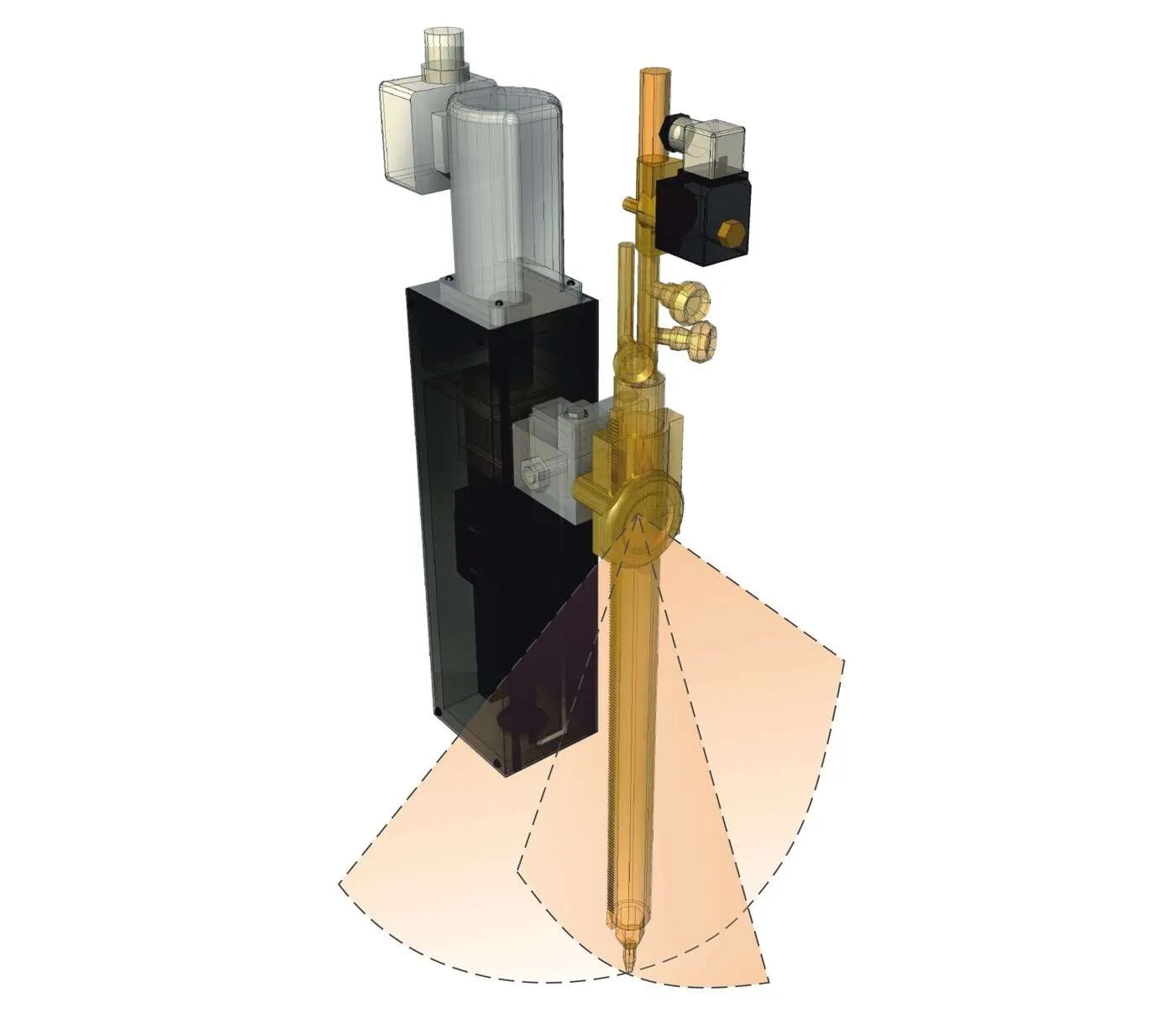

Harris Oxyfuel Torches or IHT Automated Oxyfuel Systems

Reliable Drive System with Yaskawa Drive, AC Servo Motors, and Precision Gearboxes

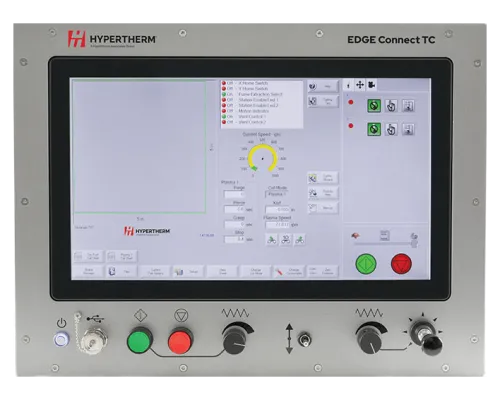

SaberCut CNC OxyFuel Cutting Machine with Hypertherm CNC Controller

The SaberCut CNC Oxyfuel Cutting Machine is a heavy-duty system designed to cut thick materials in industrial applications precisely. When equipped with the Hypertherm EDGE Connect CNC Controller, the SaberCut delivers unparalleled control, accuracy, and efficiency for oxyfuel-cutting tasks.

How the Hypertherm CNC Controller Enhances the SaberCut

- Automated oxyfuel Cutting: The Hypertherm CNC Controller enables the SaberCut to perform automated oxyfuel cutting precisely and consistently. Whether you’re cutting thick steel plates or complex shapes, the controller ensures every cut meets the highest standards.

- Advanced Process Control: The Phoenix® version 10 CNC software provides advanced process control for oxyfuel cutting, optimizing parameters such as gas flow, cutting speed, and torch height.

- Easy Setup and Operation: The Soft Operator’s Console (Soft OpCon) simplifies setup and operation.

- Real-Time Monitoring and Diagnostics: The SaberCut’s CNC controller provides real-time monitoring of key cutting parameters, such as gas pressure and torch height.

- Easy Integration with oxyfuel Systems: The EDGE Connect CNC Controller integrates seamlessly with high-quality oxyfuel torches, including Harris, Victor, and Oxweld. This integration ensures optimal performance and cut quality, even on thick materials.

- Improved Reliability: Designed for heavy-duty use, the SaberCut’s CNC controller features a fan-less quad-core processor, solid-state hard drive, and projected capacitive touchscreen.

- Customizable Performance: The EDGE Connect CNC Controller offers flexible configurations to meet specific cutting needs.

Lower Maintenance = High Performance

Automatic Lubrication System

SaberCut’s automatic lubrication system reduces manual maintenance requirements, ensuring optimal performance and longevity with minimal downtime.

Automatic Rail Scrubbers

The system includes automatic rail cleaners to prevent debris buildup on critical components, improving reliability and cutting precision while extending rail life.

Preventative Maintenance Kits

With CSI’s preventative maintenance kits, users can quickly address wear and tear, maximizing uptime and reducing costly repairs.

Engineered to Order

The SaberCut system is available in various configurations to meet specific application requirements, including custom bridge widths up to 30 feet, I-beam rail systems, and oxyfuel cutting options. This flexibility allows for tailored solutions that improve productivity, quality, and ease of operation.