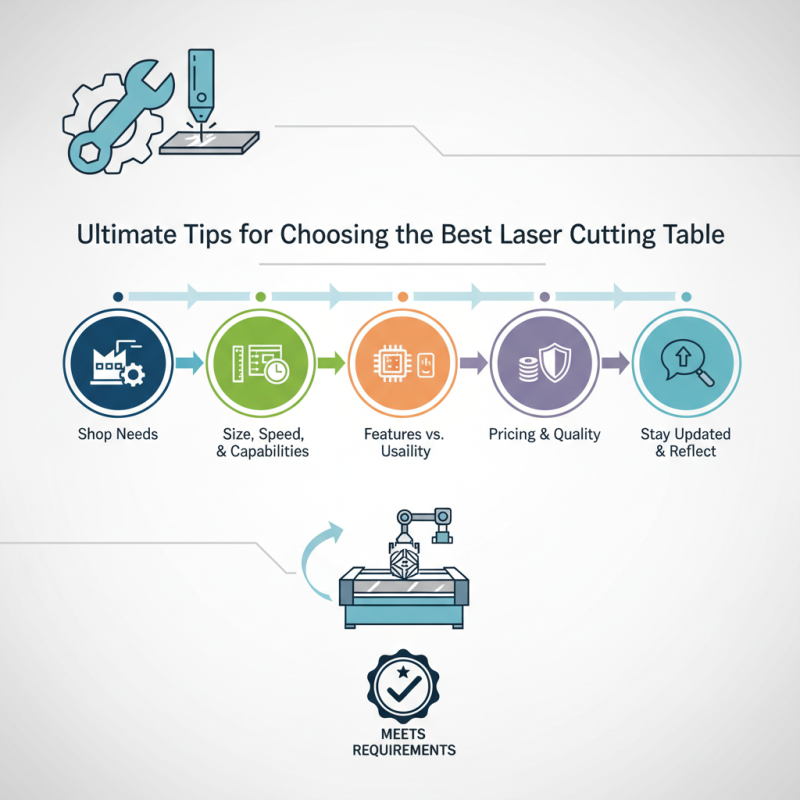

Ultimate Tips for Choosing the Best Laser Cutting Table?

Choosing the right Laser Cutting Table is crucial for any fabrication shop. According to Alan Johnson, a renowned expert in laser technology, "The best Laser Cutting Table enhances precision and reduces waste." This wisdom highlights the importance of making informed decisions about your equipment.

Selecting a Laser Cutting Table might seem straightforward. However, it involves understanding various factors. Every shop has different needs. Size, speed, and cutting capabilities vary widely among models. A table's features could greatly affect your production efficiency.

While some tables may offer advanced technology, they can also be overwhelming. It is crucial to balance features with usability. Pricing is another factor that should not overshadow quality. In this evolving industry, it’s vital to stay updated. Reflecting on your previous choices may reveal areas for improvement. By carefully evaluating these aspects, you can find a Laser Cutting Table that meets your specific requirements.

Understanding the Basics of Laser Cutting Tables

When choosing a laser cutting table, it's crucial to understand the basics. A laser cutting table is designed to be the workspace for your cutting projects. It uses a high-power laser to cut through materials accurately. Many features determine the quality of a table.

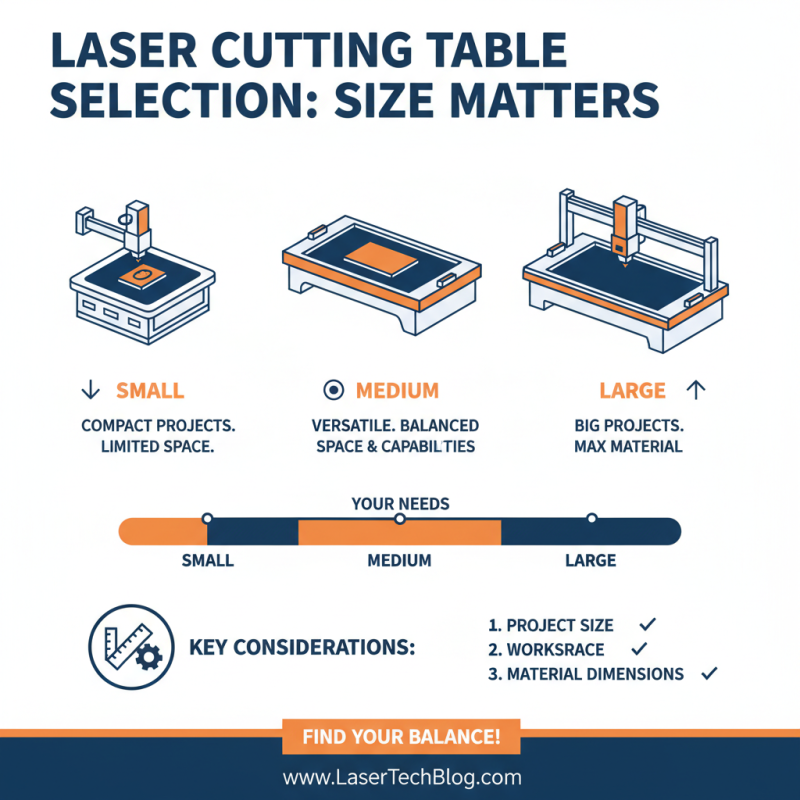

Size is an essential factor. A larger table accommodates big projects. However, it demands more space. Think about where you’ll set it up. Portability matters too. Some tables are easier to move around than others.

Next, consider the material compatibility. Different tables work well with various materials, like wood, metal, or plastic. It’s not always clear which tables perform best with specific materials. You may need to research user experiences. Are their results consistent? Not every cutting table delivers perfection. Often, adjustments are needed to achieve desired results. It's all part of the learning curve.

Key Features to Consider When Selecting a Laser Cutting Table

When selecting a laser cutting table, certain features should take priority. Size is crucial. Ensure the table accommodates your projects. A larger surface helps in handling bigger materials. However, too big may consume space. Find a balance.

Laser power affects cutting speed and material compatibility. Higher wattage means faster cuts. Yet, it might lead to material burning. Understand your typical projects before deciding on power levels.

Stability is another key aspect. A wobbly table can ruin precision cuts. Look for tables with robust builds. Adjustable legs can add value, as uneven surfaces can affect performance. Always assess the design of the table.

Consider software compatibility as well. Some tables come with proprietary software. This can limit your options when designing projects. Aim for a table that works seamlessly with various software.

Remember that maintenance matters too. Some tables need regular upkeep. Investing time in care can prevent future headaches. Lastly, budget constraints should guide your choices. Don’t overspend, but don’t compromise on essential features.

Finding the right balance is tough, but essential for laser cutting success.

Assessing the Size and Compatibility for Your Projects

When selecting a laser cutting table, the size and compatibility for your projects are crucial. Begin by assessing the dimensions of your workspace. Does the table fit comfortably? Ensure you have enough room for movement and other equipment. A cramped area can lead to mistakes and slow down your workflow.

Next, consider the materials you'll be cutting. Different projects require varying sizes and thicknesses of materials. A larger table may seem ideal, but it may be more than you need. Reflect on your common projects. Are they mostly small crafts or larger items? This will help determine the best fit for your work.

Compatibility with existing tools is equally important. A table should integrate seamlessly into your setup. Check connection options and software compatibility. Incompatible systems lead to frustration. Space analysis and material requirements must be balanced. Ensure you have the right tools before making a decision. Think critically about your needs, and don’t rush the process.

Ultimate Tips for Choosing the Best Laser Cutting Table

| Dimension | Description | Recommended Size | Compatibility |

|---|---|---|---|

| Working Area | The surface area available for cutting materials. | At least 24" x 36" | Compatible with standard sheet sizes (A2, A1) |

| Material Thickness | Maximum thickness of the material the laser can cut through. | Up to 1/2 inch for wood | Works with acrylic, wood, and metal |

| Laser Power | Power of the laser, affecting cutting speed and material type. | 50W for general use | Suitable for most engraving and cutting tasks |

| Cooling System | Type of system used to keep the laser cool during operation. | Water-cooled recommended | Enhances performance and longevity |

| Software Compatibility | Software required for design and cutting operations. | Supports DXF, AI, and SVG formats | Compatible with major design software |

Comparing Different Laser Cutting Technologies on the Market

When comparing laser cutting technologies, it's essential to consider the specific requirements of your projects. CO2 lasers are widely used for materials like wood, acrylic, and textiles. They provide a good balance between cost and performance. Research indicates that CO2 lasers have a power range of 30W to 150W, depending on thickness and material types.

Fiber lasers are gaining popularity for their efficiency and precision. They can cut metals with ease, outperforming CO2 in speed and operating costs. Reports show fiber lasers offer over 90% electrical efficiency. However, they may struggle with non-metal materials, which limits versatility. Not all applications benefit equally from different technologies, so understanding your needs is crucial.

Efficiency also plays a big role. Some laser systems, despite their advanced features, may not deliver the anticipated productivity. Users have reported underperformance in high-demand environments. It's vital to analyze machine specifications against real-world use cases. Investing in a laser cutting table requires a clear understanding of materials, cutting speeds, and operational costs. A well-rounded decision can still have pitfalls. Always seek feedback from real users about their experiences.

Comparison of Laser Cutting Technologies

Evaluating Budget and Value: Finding the Right Price Point

When selecting the right laser cutting table, budget is crucial. Assess your project's needs first.

Think about the materials you'll work with. A solid machine may cost more upfront but can save money in the long run. High-quality tables often have better durability and precision.

Reflect on your expected usage. A light-duty table might not withstand high demand.

Make a price comparison between various options. Consider looking at features that enhance value. Some tables have adjustable settings, while others come with more powerful lasers.

Ask yourself: Are these features necessary for your work? Sometimes, extra options drive up costs but don’t add much to productivity.

Don't overlook maintenance costs too. A cheaper table might require more repairs.

Balance price with potential expenses. Investing wisely means thinking beyond initial price tags. Understand long-term value versus short-term savings.

Aim for a table that meets your specific needs without breaking the bank.

Related Posts

-

Industry Applications of Laser Cutting Tables and 7 Benefits You Might Not Know

-

Revolutionize Your Workshop with Advanced Laser Cutting Table Technology

-

Elevate Your Manufacturing with Plasma CNC Machines at the 137th Canton Fair: Insights from Global Buyers

-

Unlocking Precision Cutting with the Best Cnc Plasma Table Specifications and Usage Guide

-

10 Ways Cnc Plasma Cutting Tables Transform Your Manufacturing Efficiency

-

Resilient Growth of Chinese Manufacturers in the Face of US China Tariffs and the Rise of Best Small CNC Plasma Cutters