Ultimate Guide to Maximizing Efficiency with CNC Plasma Cutting Machines

In today's fast-paced manufacturing environment, maximizing efficiency is a crucial factor for success, and one of the most effective tools at a shop's disposal is the CNC plasma cutting machine. This advanced technology not only enhances cutting precision but also significantly reduces production time, making it a favorite among fabricators and manufacturers alike. However, simply having a CNC plasma cutting machine is not enough; understanding how to leverage its full potential can lead to remarkable gains in productivity and cost savings. This ultimate guide delves into various solutions and strategies for optimizing the use of CNC plasma cutting machines, ensuring operators can harness their capabilities to streamline workflows, minimize waste, and improve overall output. Whether you are a seasoned professional or new to the world of CNC plasma cutting, this guide offers valuable insights to help you maximize the efficiency of your operations.

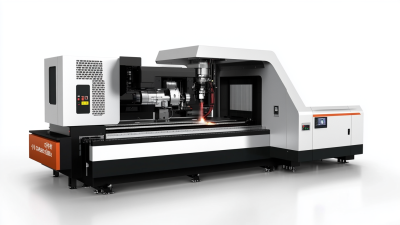

Maximizing Production Speed: Comparing Different CNC Plasma Cutting Machines

When it comes to maximizing production speed in CNC plasma cutting, understanding the nuances between different machines is crucial. The advancement in technologies, such as CNC plasma cutting, paired with innovations in materials, has transformed the machining landscape. For instance, recent studies on the machinability of LM25 aluminum alloy reinforced with vanadium carbide composite materials indicate that optimizing machining processes can enhance efficiency significantly. By utilizing analytical modeling and advanced techniques like deep neural networks, manufacturers can fine-tune their operations, leading to more effective and faster production cycles.

China’s ascendance as a hub for innovation in advanced manufacturing has also influenced CNC plasma cutting technologies. With universities and local companies pushing the boundaries of research and development, a variety of CNC plasma cutting machines have emerged, each with unique capabilities designed to handle complex materials like the LM25Al/VC composite. This innovation not only helps manufacturers achieve higher production speeds but also enables them to maintain superior quality in their outputs. Understanding the features and advantages of each machine is essential for businesses looking to enhance their machining operations and stay competitive in an ever-evolving market.

Understanding Different Types of CNC Plasma Cutting Technologies and Their Benefits

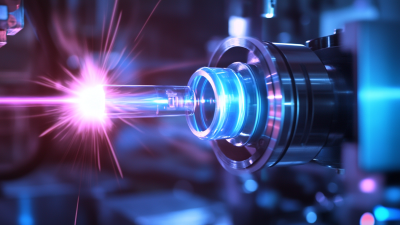

CNC plasma cutting technology has revolutionized the manufacturing industry by offering high precision and efficiency. Understanding the various types of CNC plasma cutting technologies can significantly enhance operational productivity. For instance, High Definition (HD) plasma cutting machines provide remarkable edge quality and minimal dross formation, making them ideal for complex designs. Reports indicate that using HD plasma over traditional methods can increase cut speeds by 50% while reducing operational costs by up to 30%.

CNC plasma cutting technology has revolutionized the manufacturing industry by offering high precision and efficiency. Understanding the various types of CNC plasma cutting technologies can significantly enhance operational productivity. For instance, High Definition (HD) plasma cutting machines provide remarkable edge quality and minimal dross formation, making them ideal for complex designs. Reports indicate that using HD plasma over traditional methods can increase cut speeds by 50% while reducing operational costs by up to 30%.

When selecting a CNC plasma cutting machine, it’s crucial to assess the capabilities of different technologies. Mechanized plasma cutting systems, which utilize a computer-controlled motion system, can handle intricate geometries with ease, enabling manufacturers to produce parts that meet stringent specifications. The Global Plasma Cutting Machines Market report estimates a compound annual growth rate (CAGR) of 6.5%, underscoring the growing demand for advanced plasma cutting solutions.

Tip: Regular maintenance of your CNC plasma cutting machine can prevent breakdowns and extend its lifespan, maintaining efficiency. Also, experimenting with different gas mixtures can optimize cut quality and speed, enhancing overall production capabilities. Additionally, investing in software that integrates seamlessly with CNC control can streamline programming and increase throughput.

Key Factors Influencing Efficiency in CNC Plasma Cutting Processes

Efficiency in CNC plasma cutting processes is influenced by several key factors that can enhance performance and productivity. Firstly, the quality of the plasma cutting machine plays a crucial role; machines equipped with advanced technology allow for faster cutting speeds and more precise cuts. Additionally, the type of consumables used, such as nozzles and electrodes, can significantly impact operational efficiency. High-quality consumables ensure optimal energy transfer and prolong the lifespan of the cutting equipment, reducing downtime for maintenance.

Furthermore, operator skill and training are paramount in maximising the efficiency of CNC plasma cutting machines. Proficient operators can set the machines accurately, adjust settings for different materials, and troubleshoot issues on the fly. This not only saves time but also minimizes waste by improving the cut accuracy. Lastly, regular maintenance and timely upgrades to software and hardware can keep machines running at peak performance, adapting to evolving industrial needs and ensuring that operational efficiency is maximized throughout the cutting process.

Efficiency Factors in CNC Plasma Cutting Machines

Industry Standards and Best Practices for CNC Plasma Cutting Optimization

The efficiency of CNC plasma cutting machines is heavily influenced by adherence to industry standards and best practices. According to a report by the Fabricators & Manufacturers Association (FMA), optimizing cutting speed and power settings can yield up to a 30% increase in productivity. Properly calibrated machines ensure precision in cutting, reducing wasted material and minimizing the need for post-processing. Regular maintenance, as outlined in the American Welding Society (AWS) guidelines, is crucial; routine checks can identify wear on consumables, which, if neglected, can lead to errors costing manufacturers significant resources.

Incorporating best practices such as automated nesting software can enhance material utilization by up to 20%, as reported by a survey from the Association for Manufacturing Technology (AMT). Additionally, using high-quality plasma gases plays a vital role in maintaining cut quality and speed. A study demonstrated that switching to oxygen instead of air for cutting steel resulted in cleaner edges and reduced dross, leading to a remarkable decrease in secondary operations. By following these industry standards and integrating advanced technologies, manufacturers can not only achieve enhanced efficiency but also ensure consistent quality in their CNC plasma cutting processes.

The Impact of Material Types on CNC Plasma Cutting Efficiency and Results

When it comes to CNC plasma cutting, the type of material you choose can significantly influence both efficiency and end results. Different materials, such as steel, aluminum, and copper, exhibit varying thermal conductivity and melting points, which can alter the cutting speed and quality. For instance, while mild steel is generally the easiest to cut, aluminum tends to require finer adjustments to the machine settings for optimal results.

**Tip:** Always conduct a test cut on a scrap piece of the same material to fine-tune your settings. This practice ensures that you achieve the desired edge quality and speed without wasting valuable material.

In addition, the thickness of the material plays a crucial role in how effectively a CNC plasma cutting machine operates. Thicker materials require more power and can produce more dross if not properly adjusted. Conversely, thinner materials can be cut at higher speeds without compromising quality.

**Tip:** Consider using a plasma cutting machine with adjustable amperage settings to match the material thickness. This allows for precise cuts and minimizes the risk of damaging thinner materials during the process. By tailoring your approach to the specific material at hand, you can maximize both efficiency and output.

Ultimate Guide to Maximizing Efficiency with CNC Plasma Cutting Machines - The Impact of Material Types on CNC Plasma Cutting Efficiency and Results

| Material Type | Thickness (mm) | Cutting Speed (m/min) | Efficiency (%) | Edge Quality Rating (1-10) |

|---|---|---|---|---|

| Mild Steel | 10 | 5 | 85 | 8 |

| Stainless Steel | 8 | 4 | 80 | 7 |

| Aluminum | 6 | 6 | 90 | 9 |

| Copper | 5 | 3 | 75 | 6 |

| Nickel | 4 | 3.5 | 70 | 5 |

Related Posts

-

How to Choose the Best Cnc Plasma Cutting Machine for Your Business Needs

-

Global Manufacturing Guidelines for Cnc Plasma Cutting Machine Innovations

-

Challenges When Choosing the Right Best Cnc Plasma Table for Your Business Needs

-

Elevate Your Manufacturing with Plasma CNC Machines at the 137th Canton Fair: Insights from Global Buyers

-

Resilient Growth of Chinese Manufacturers in the Face of US China Tariffs and the Rise of Best Small CNC Plasma Cutters

-

Exploring Real World Applications of the Best Plasma Torch Across Diverse Industries