How to Choose the Best CNC Plasma Cutting Table for Your Needs?

Choosing the right CNC Plasma Cutting Table can be daunting. The market offers a wide range of options tailored to various needs and applications. According to industry reports, the CNC plasma cutting market is expected to grow significantly, reaching over $9 billion by 2025. This growth highlights the increasing importance of precision cutting in industries like manufacturing and metalworking.

When selecting a CNC Plasma Cutting Table, consider your specific requirements. Different tables come with varying sizes, features, and price points. Some models cater to small workshops, while others are designed for large-scale operations. Misjudging your needs can lead to inefficiency and increased costs. For instance, choosing a table that is too small may limit your projects or create material waste.

Most users focus solely on price. However, features and reliability are crucial. A lower-priced option might lack the durability you need for daily tasks. The wrong choice can hinder productivity and impact the quality of your work. Reflecting on long-term goals is essential for making the right decision. Investing in a high-quality CNC Plasma Cutting Table can ultimately pay off, enhancing your capabilities and results.

Understanding CNC Plasma Cutting Tables and Their Applications

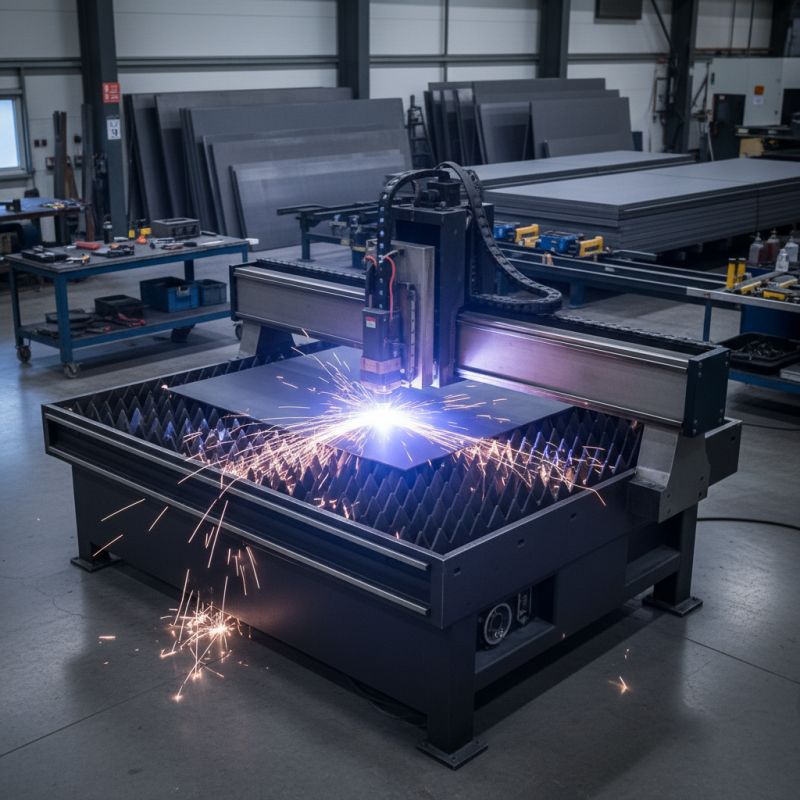

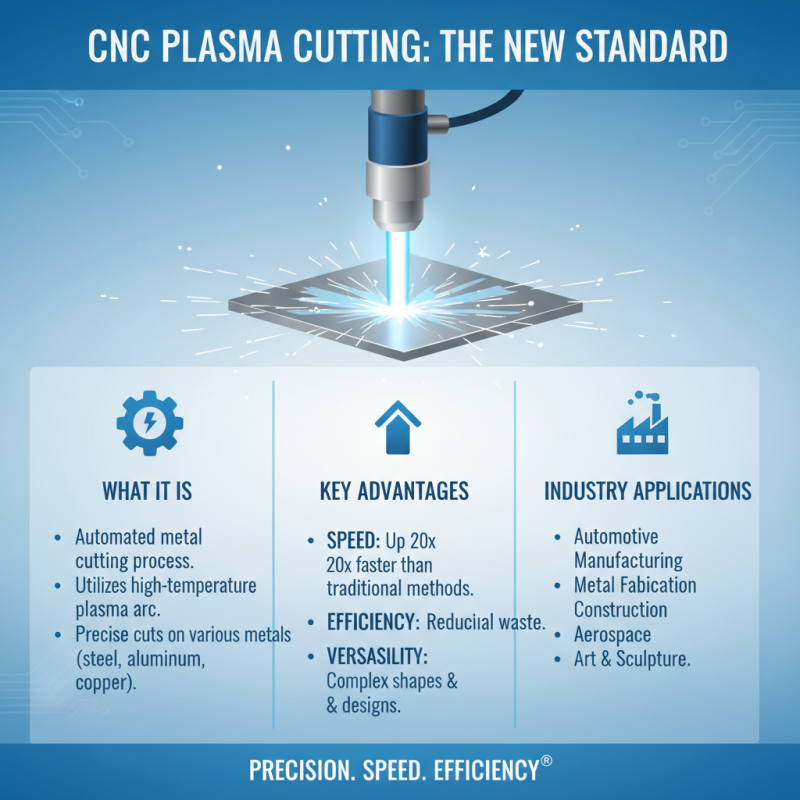

CNC plasma cutting tables are essential in various industries, from metalworking to automotive. These machines use high-temperature plasma to cut through metals with precision. This technology reduces material waste and increases efficiency in production. In fact, reports indicate that plasma cutting can achieve a speed of up to 20 times faster than traditional cutting methods.

Understanding the applications of CNC plasma cutting tables is crucial. They are often used for structural steel fabrication and pipe cutting. A study showed that about 40% of metal fabricators utilize plasma cutting technology. This highlights its importance in manufacturing sectors. However, selecting the right CNC table is not always straightforward. It requires a balance of power requirements, table size, and compatibility with different materials.

Sometimes, users overlook specific features that could enhance their work. For instance, the ability to easily adjust cutting speeds is vital for various materials. Inadequate attention to these details can lead to inefficiency, making it essential to reflect on the features that matter most for specific tasks.

Key Factors to Consider When Choosing a CNC Plasma Cutting Table

Choosing the right CNC plasma cutting table requires careful consideration. One of the key factors is the size of the table. Think about the materials you will cut and the maximum dimensions involved. A table that is too small can limit your projects. Moreover, a larger table may take up a lot of space. Balance is crucial.

Another important factor is the cutting thickness. Different tables have varying capacities. It’s essential to know the types of materials you'll work with. If you need to cut thicker metal, ensure the table can handle that. On the flip side, if you often cut thin material, a high-powered table may not be necessary.

**Tips:** Always check the power supply requirements. Ensure it aligns with your workshop’s capabilities. Also, consider ease of use. A complicated setup can slow down productivity. Lastly, think about the support and training offered with the table. You want to make sure you can operate it effectively. Reflect on your needs versus high-tech features. Sometimes, simplicity can lead to better outcomes.

How to Choose the Best CNC Plasma Cutting Table for Your Needs?

| Feature | Description | Importance |

|---|---|---|

| Size of the Table | Determines the maximum workpiece dimensions you can handle. | High |

| Material Thickness | Indicates the type and thickness of materials the table can cut. | High |

| Cutting Speed | Speed at which the table can perform cuts, affecting productivity. | Medium |

| Precision | Accuracy of cuts made by the plasma cutter. | High |

| Software Compatibility | Compatibility with design software for efficient workflow. | Medium |

| Portability | Ease of moving the table for different job sites. | Low |

| Maintenance and Support | Availability of parts and customer support for repairs. | High |

Comparing Different Types of CNC Plasma Cutting Tables

When comparing different types of CNC plasma cutting tables, several factors come into play. The size of the table is crucial. A larger table provides more workspace, allowing for bigger projects. However, it can also take up more shop space. Industry reports indicate that tables between 4x8 feet and 5x10 feet are the most popular for general use. They balance space and utility well.

Another important factor is the drive system. There are two main types: belt-driven and rack-and-pinion systems. Belt-driven systems offer smooth movements. However, they may wear down quicker than their counterparts. The rack-and-pinion system, while sturdier, can be less precise in some scenarios. Keep in mind that this choice will affect long-term operational costs.

**Tip:** Consider purchasing a table with modular design features. This allows for easier upgrades as your needs evolve.

Additionally, assess the power source. Different CNC plasma tables require varying amperage and voltage. Some can handle metal up to an inch thick, while others perform better with thinner materials. A mismatched power supply can lead to poor cutting quality. Investing in a table with adjustable power settings can prevent future issues.

**Tip:** Perform a trial cut before finalizing your choice. This assessment can reveal potential shortcomings in the machine. Not all tables perform equally. Always double-check the specifications based on your specific projects.

Comparison of Different Types of CNC Plasma Cutting Tables

Budgeting for Your CNC Plasma Cutting Table Investment

When budgeting for a CNC plasma cutting table, it's crucial to assess your specific needs first. Different projects may require varying capabilities. Consider the materials you'll be cutting and the thickness range. Knowing this helps narrow down your options effectively.

Next, reflect on your available budget. A high-end plasma table may offer advanced features, but does it suit your work? Sometimes, a mid-range model will suffice for your tasks. Look for essential features like cutting speed and precision without overspending.

You might also want to factor in additional costs. Maintenance, replacement parts, and consumables can add up. Taking the time to explore different price points can lead to better choices. It's important not to rush this decision, as a poorly chosen table could lead to regret down the line. Decide carefully, balancing needs with financial limits.

Maintenance and Support for Your CNC Plasma Cutting Table

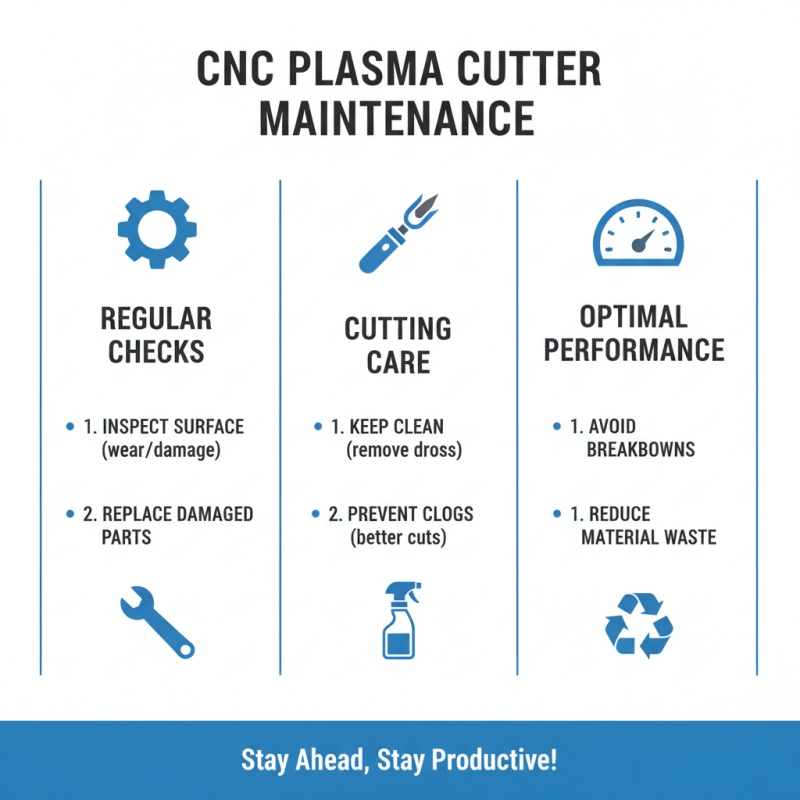

Maintaining a CNC plasma cutting table is crucial for optimal performance. Regular checks can prevent unexpected breakdowns. Inspect the table’s surface for any signs of wear. Replace damaged parts immediately to avoid bigger issues. Keep the cutting torch clean. A clogged torch can lead to poor cuts and wasted materials.

Support is just as important. Access to reliable customer service can save time and frustration. Having a knowledgeable support team available ensures quick troubleshooting. Users often overlook manuals until it’s too late. Referencing the manual can clarify maintenance steps. Online resources may also provide helpful tips.

Consider training options for your team. Well-trained operators can maximize the table's capabilities. Yet, some may skip this step. Investing in training pays off in efficiency and quality. Learning from mistakes enhances overall productivity. Balancing maintenance and support fosters a better cutting experience.

Related Posts

-

Ultimate Guide to Maximizing Efficiency with CNC Plasma Cutting Machines

-

Understanding the Advantages of the Best CNC Plasma Table for Your Manufacturing Needs

-

How to Choose the Best Plasma Table for Your Business Needs

-

How to Choose the Best Cnc Plasma Cutting Machine for Your Business Needs

-

10 Ways Cnc Plasma Cutting Tables Transform Your Manufacturing Efficiency

-

Innovative Applications of Cnc Plasma Cutting Machine in Various Industries