7 Reasons Why the Best CNC Cutter Can Transform Your Manufacturing Process

In today's highly competitive manufacturing landscape, the choice of equipment can make or break your operation's efficiency and output quality. Among the myriad of tools available, the CNC cutter stands out as a transformative force in modern manufacturing processes. With its precision, versatility, and automation capabilities, a high-quality CNC cutter doesn’t just improve production speed; it elevates the overall craftsmanship of the products being created. This blog will explore seven compelling reasons why investing in the best CNC cutter can revolutionize your manufacturing workflow. From enhancing cutting accuracy to minimizing waste and reducing labor costs, understanding the profound benefits of a superior CNC cutter is essential for manufacturers looking to streamline their operations and stay ahead of the competition.

Key Industries Revolutionized by CNC Cutters

In today's rapidly evolving manufacturing landscape, CNC cutters are pivotal in transforming key industries, from aerospace to automotive. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $117.5 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth is largely driven by the demand for precision and efficiency, particularly in sectors that require intricate designs and high production speeds. For instance, the aerospace industry, with a need for lightweight and durable components, has effectively utilized CNC technology to enhance the accuracy of parts while significantly reducing waste.

Moreover, the automotive sector has also recognized the transformative capabilities of CNC cutters. A study by Grand View Research indicates that the global automotive CNC market is expected to grow at a CAGR of 7.5% over the next several years. CNC cutters enable manufacturers to produce complex geometries and high-tolerance components that meet strict regulatory standards. This precision not only improves vehicle performance but also accelerates production timelines—crucial in a market where speed to market can significantly impact competitiveness. As industries continue to embrace automation, the role of CNC cutters will only expand, driving efficiency and innovation across the board.

Impact of CNC Cutters on Key Industries

How CNC Cutters Enhance Precision in Manufacturing

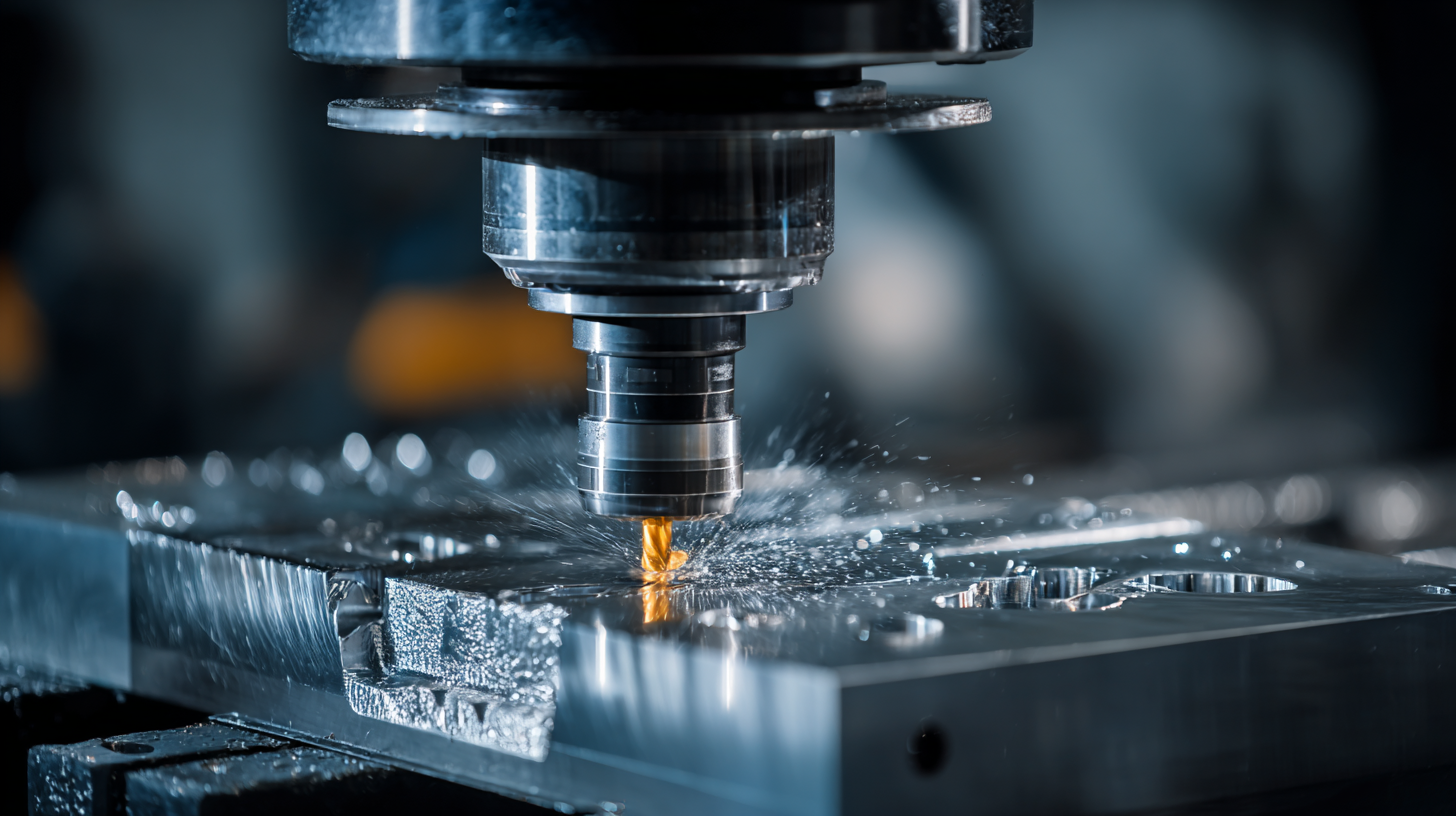

CNC cutters are revolutionizing the manufacturing landscape by enhancing precision and efficiency. The technology allows for intricate designs and precision cuts that significantly improve product quality. Automated CNC plasma cutters, for example, can achieve tolerances that manual methods simply cannot match. This level of precision minimizes waste and reduces the need for rework, ultimately leading to cost savings and smoother production processes.

When considering a CNC cutter for your manufacturing needs, it's essential to examine the specific type that best suits your applications. For instance, CNC plasma cutting machines excel in delivering high-quality cuts rapidly, making them ideal for industries like metal fabrication. On the other hand, CNC tool and cutter grinding machines are crucial for businesses focusing on the precision engineering of tools.

Tips for maximizing the benefits of CNC cutters include regular maintenance to ensure optimal performance and investing in skilled operators who understand the nuances of the technology. Furthermore, integrating CNC machines with advanced software can streamline the workflow and enhance the overall productivity of the manufacturing process. By embracing these strategies, businesses can fully leverage the advantages of CNC technology.

Real-World Applications: Success Stories of CNC Implementation

In today's manufacturing landscape, CNC cutters are revolutionizing production processes across various industries. Real-world success stories illustrate this transformation, showcasing how businesses have streamlined operations and enhanced precision. For example, a custom furniture company was able to reduce waste and improve design accuracy by implementing advanced CNC technology, ultimately leading to higher customer satisfaction and lower operational costs.

One key tip for maximizing the benefits of CNC implementation is to invest in proper training for operators. Empowering your team with the right skills will ensure they can fully leverage the machine's capabilities, enhancing overall productivity. Additionally, integrating CNC cutters with existing systems can improve workflow efficiency. By automating repetitive tasks, manufacturers can redirect human resources to more critical areas, thereby fostering innovation.

Another compelling case is found in the automotive industry, where a team reduced machining time by 40% through CNC cutting. This was achieved by optimizing design files for the CNC process. To replicate such success, consider regularly reviewing and refining your design files. This practice not only boosts efficiency but also ensures consistent output quality, a vital factor for meeting the high standards of today's manufacturing demands.

Step-by-Step Guide to Integrating CNC Cutters in Your Workflow

Integrating CNC cutters into your manufacturing workflow can streamline processes, enhance precision, and ultimately boost productivity. The first step in this transformation is to assess your current production methods. Identify bottlenecks and areas where manual cutting is causing delays or inconsistencies. Once you have a clear understanding of your workflow, you can pinpoint where a CNC cutter will fit best, whether it's in cutting, engraving, or shaping materials.

Next, it's crucial to choose the right CNC cutter for your specific needs. Assess factors like cutting speed, material compatibility, and ease of use. After selecting the machine, focus on training your team. Proper training ensures that your operators can maximize the capabilities of the CNC cutter, leading to better output quality.

Additionally, integrating software that works seamlessly with your CNC machine can facilitate smoother operations and improve communication across different departments in your manufacturing process. By taking these steps, you can harness the full potential of CNC technology, transforming not just how you cut materials, but how your entire manufacturing process operates.

The Future of Manufacturing: Innovations in CNC Cutting Technology

The future of manufacturing is heavily influenced by innovations in

CNC cutting technology, which plays a pivotal role in enhancing efficiency and precision

in production processes. As manufacturers adopt advanced CNC cutters, they benefit from improved material utilization,

reducing waste and lowering costs. The integration of AI and

machine learning into CNC systems allows for real-time adjustments,

optimizing cutting paths and parameters to achieve the highest accuracy. This adaptability is crucial as industries demand

increasingly complex and customized solutions.

Moreover, new developments in CNC technology, such as multi-axis cutting

and hybrid manufacturing techniques, offer unprecedented versatility.

These innovations enable manufacturers to create intricate designs that were previously unattainable while maintaining high

production speeds. With features like automated tool changes and enhanced programmability, modern CNC cutters not only

streamline operations but also empower workers to focus on value-added tasks rather than repetitive, manual labor. As the

landscape of manufacturing continues to evolve, embracing these cutting-edge technologies is essential for

staying competitive and meeting the diverse needs of today's markets.